Last updated on September 26th, 2022 at 01:55 am

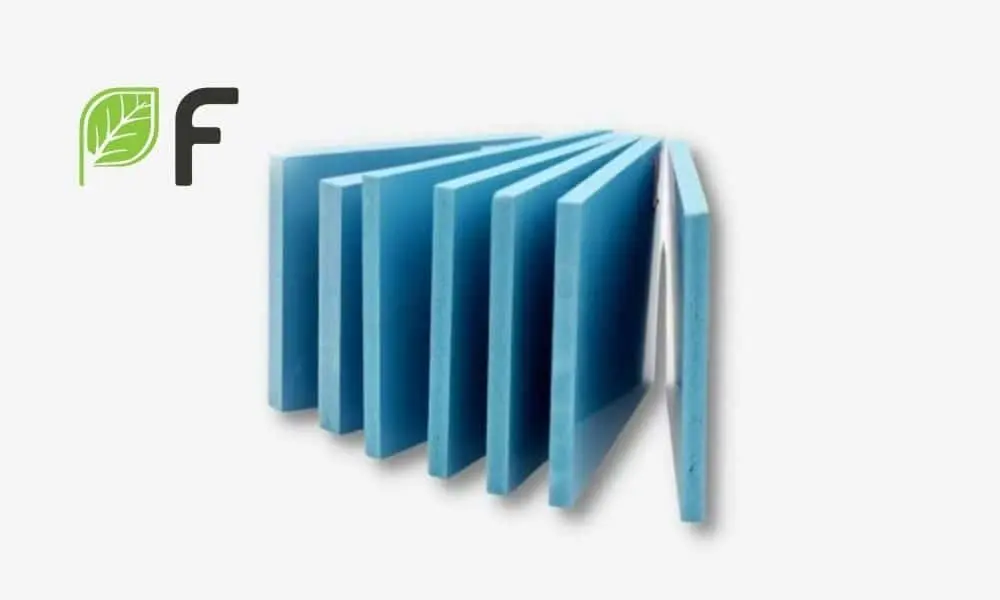

One of the most important aspects that businesses in the construction industry rely on is the right formwork for buildings. In order to ensure top quality and control costs, selecting and utilizing the best suited formwork is key. Keeping this importance in mind, plastic formwork has become one of the more sought-after types over the last few years.

The reason for this increase in the use of plastic formworks has been debated countless times. There are numerous advantages of plastic formworks that have helped the construction industry immensely. At the same time, there are a few negatives involved as well, especially in today’s unstable world ecosystem. Do the positives outweigh the negatives, though? Read on to learn about plastic formwork, its advantages, and disadvantages, and perhaps understand whether or not it’s a boon.

What are formworks?

Formworks are moulds using which the building blocks of construction are created and shaped. The formwork essentially holds the concrete together in predetermined shapes and sizes until it sets. Studies have shown that formworks contribute to almost 25% of a construction’s success, determining the speed, safety, and financial factors of the project. This is why choosing the right formwork material and process is a crucial component of the construction business.

Formworks can be made out of different materials such as steel, aluminum, timber, and more recently, plastic. Each has its own set of advantages and drawbacks depending on the type of construction and other factors. Today, we’ll discuss the advantages and disadvantages of plastic formworks as compared to others in the construction industry.

Why have plastic formworks become so popular among construction businesses? What is the objective of using formwork in construction? What factors impact a construction business negatively where plastic formworks are concerned. These are some of the questions we’ll help you answer.

Purpose of using formworks in construction

The reason we’re discussing the advantages of plastic formworks and their drawbacks is simple. In order to understand the role of plastic formworks, we need to first understand its purpose.

Formworks, as stated before, are not part of permanent construction, but act as a support system to get work done. Despite it being a temporary structure, it is important to pay attention to formworks in order to prevent damages. There are three main factors that impact formwork and define the purpose for which they are used.

- Safety — the most important purpose of using formworks is to ensure the safety of concrete construction. Formworks help provide a strong foundation for concrete structures until they’re able to hold their own. If the formwork is not strong enough to support the concrete, it can cause irreparable damage. This is not just to the structure, but to the labour and the general public as well.

- Accuracy — any construction requires the utmost accuracy of its finished product for it to be considered a success. The quality of the completed structures depends on the quality of its formwork.

- Budget — formworks play a large role in drafting the budget of a construction project. Formworks support the backbone of a building. its structural framework. If the process of making the framework doesn’t flow smoothly, it could have huge impacts on the budget.

Keeping these 3 critical factors in mind, let’s now understand where plastic formworks fit into the construction industry.

Advantages of Plastic Formworks

The many advantages of plastic formworks are why it has become one of the most commonly used in recent years. Studies have shown a huge increase in contracts for plastic formworks as compared to other materials. Let’s now delve into some of the many benefits it offers in the construction world.

- Light weight and easy to handle — plastic formworks, as compared to traditional timber or steel formwork, is very light in weight. This makes it easy to use not just in terms of laying and adjustments, but also for transportation.

- Water and rust resistance — an important differentiating factor between plastics and other formwork is their resistance to water, rust, corrosion, and alkali substances. This makes plastic especially suited for areas like underground constructions and damp areas.

- Reusability — high-grade plastic formworks don’t need to be disposed of after a single use like with other formworks. They can be reused several times until they reach the end of their lifecycle. Lower-grade plastics can also be recycled and used to make new formwork easily.

- Low maintenance — plastic formworks require almost no maintenance throughout its lifespan. Poured concrete doesn’t stick to the plastic material and neither are there any chemical reactions to worry about. Once the concrete is set and the formworks removed, they are very easy to clean using just water.

- Cost-effective — the various benefits mentioned above contribute to this advantage of plastic formworks cost-effectiveness. The reusability and recycling capability of plastic formworks ease the financial burden a lot as compared to other formworks.

- Sizing capability — unlike other formworks such as steel and timber, plastic formworks can be molded to fit any size as required. With no restrictions on size and shape, this is a huge advantage of plastic formworks.

Disadvantages of Plastic Formworks

Although a clearly preferred choice as per the current construction trends, there are certain disadvantages of plastic formworks to consider. Let’s look at some of them now.

- Lack of heat endurance — plastic formworks, though very flexible and tough, don’t have the ability to endure high levels of heat. The thermal expansion and contraction capacity of plastics is higher as compared to steel or wood. This can be an issue in places that see high daytime temperatures, causing the plastic formwork to stretch.

- Load-bearing capacity — high-quality plastic formworks are quite sturdy and can support huge loads up to a certain amount. However, it does not have immensely high load-bearing capabilities as compared to timber or steel. Additionally, the static bending ability of plastic formworks made from regular plastic is very less compared to other formworks.

- High flexibility — sometimes, the high flexibility levels can become a disadvantage of plastic formworks. Although helpful in building various shapes and holding concrete to different sizes, the flexibility may cause slight fluctuations at times.

- Cost factor — plastic moulds are more expensive than traditional variants like plywood and aluminum. This may lead to an increase in the one-time costs of material during the initial phases of the construction project. However, this disadvantage of plastic formworks is relevant only during the initial project phase. In the long run, it could very well turn into an advantage of plastic formworks.

Bottom line!

Plastic formworks are, without a doubt, one of the best things to have happened to the construction industry. The advantages of plastic formworks listed above just touch the tip of the iceberg. On the whole, plastic formworks are instrumental in speeding up the construction process and reducing costs along the way. They are reusable up to 30 times more than other formwork types. The toughness, flexibility, and labor-friendly aspects only add to its value in the construction world.

Yes, there are some disadvantages of plastic formworks as discussed earlier, but the benefits far outweigh the negatives. In fact, the drawbacks like heat-resistance and load capacity are aspects that can be countered by reinforcements and vacuum-formed plastics. Our conclusion, therefore, is that plastic formworks are indeed a boon to the construction industry. We are sure to see it uses growing manifold in the years to come.