Last updated on October 19th, 2024 at 03:20 am

In the fast-paced world of construction, efficiency, cost-effectiveness, and sustainability are top priorities. While traditional methods may have been the norm for years, the industry is embracing innovative solutions that meet modern challenges. One such game-changing innovation is reusable plastic formwork. By transforming how concrete structures are built, this cutting-edge technology offers a more sustainable and cost-efficient alternative to conventional formwork systems.

This ultimate guide will walk you through everything you need to know about reusable plastic formwork, from its benefits and applications to how it can significantly transform your construction projects.

What Is Reusable Plastic Formwork?

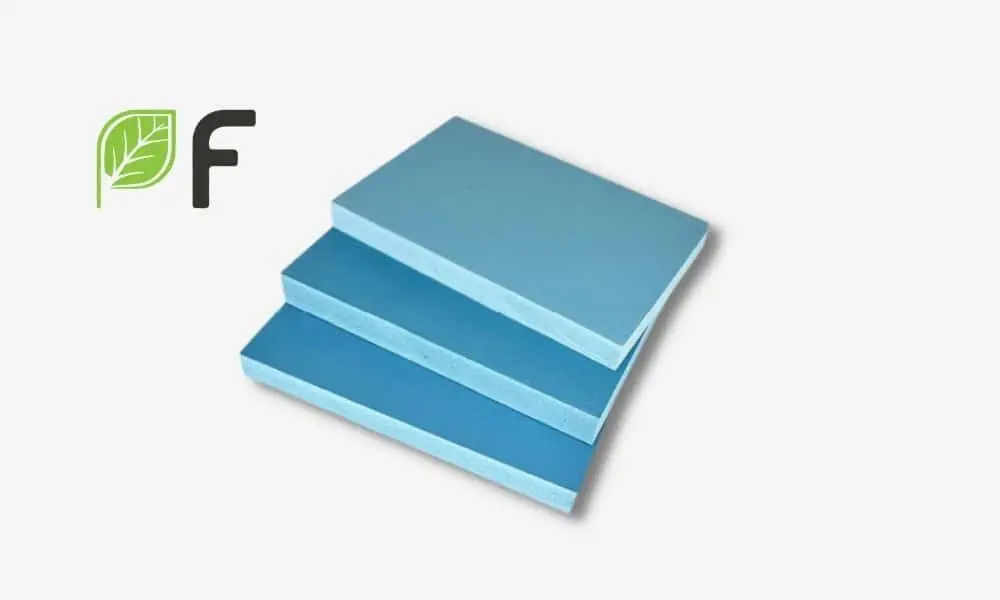

Reusable plastic formwork is a type of formwork made from durable, high-strength plastic materials designed to withstand the pressures of casting concrete. Unlike traditional formwork systems made from timber, steel, or plywood, plastic formwork is designed to be lightweight, easy to handle, and, most importantly, reusable for multiple construction projects.

Its modular nature allows it to be easily assembled, adjusted, and dismantled, making it an ideal solution for projects that require flexibility and efficiency. Reusable plastic formwork is most commonly used in casting concrete walls, slabs, columns, and foundations, and is gaining popularity due to its environmental benefits and cost-saving potential.

The Key Benefits of Reusable Plastic Formwork

Choosing reusable plastic formwork for your construction projects can provide a wide range of advantages, including:

Cost-Effectiveness

While the initial cost of reusable plastic formwork may be higher than traditional options, its long-term financial benefits are significant. Since plastic formwork can be reused for multiple projects, the overall cost per use decreases. Traditional formwork materials like timber or plywood often need to be replaced after a few uses due to wear and tear, while plastic formwork can last for hundreds of cycles.

This reusability drastically reduces material costs, leading to greater profitability over time. For construction firms looking to optimize budgets, plastic formwork is a strategic investment that pays off in the long run.

Durability

Made from high-quality, resilient materials, plastic formwork is highly resistant to water, chemicals, and the natural degradation that affects traditional wooden or metal formwork. Unlike wood, which can absorb moisture and become warped or cracked, plastic formwork maintains its structural integrity, even in harsh weather conditions.

This durability ensures that your formwork remains in excellent condition for multiple uses, reducing the need for constant repairs or replacements. This makes it especially valuable for long-term construction projects or those located in environments with extreme weather conditions.

Lightweight and Easy to Handle

Plastic formwork is significantly lighter than steel or timber formwork, making it easier to transport, install, and dismantle. The lightweight nature of plastic formwork also minimizes the need for heavy lifting equipment, reducing labor costs and accelerating project timelines.

For construction teams looking to boost efficiency, the ease of handling reusable plastic formwork can significantly reduce project downtime and streamline construction processes.

Sustainability

In an industry where sustainability is becoming increasingly important, plastic formwork stands out as an eco-friendly alternative to traditional materials. Because it can be used multiple times, plastic formwork reduces the demand for new materials, leading to less deforestation and waste generation. Traditional timber formwork contributes to the depletion of natural resources, while plastic formwork helps reduce your project’s environmental footprint.

Moreover, many manufacturers now produce plastic formwork using recycled materials, further enhancing its green credentials. Choosing reusable plastic formwork demonstrates your commitment to sustainability and aligns your projects with the latest green building standards.

Faster Assembly and Dismantling

The modular design of plastic formwork allows for quick and easy assembly and dismantling, helping construction teams save valuable time. The formwork can be adjusted to suit different project dimensions, making it versatile and adaptable to various construction needs. This faster turnaround time not only increases productivity but also reduces labor costs.

For projects where time is a critical factor, reusable plastic formwork is an ideal solution that can accelerate your construction process while maintaining high-quality results.

High-Quality Concrete Finish

Plastic formwork provides a smooth, even surface that results in high-quality concrete finishes with minimal imperfections. This reduces the need for additional finishing work, such as plastering or surface corrections, further cutting down on labor and material costs. The precision of plastic formwork ensures that your finished structure will meet the highest standards of craftsmanship, saving time on post-construction tasks.

Applications of Reusable Plastic Formwork

Reusable plastic formwork is incredibly versatile and can be used in a variety of construction projects. Here are some of its most common applications:

Walls and Columns

Plastic formwork is ideal for casting concrete walls and columns in both residential and commercial projects. Its lightweight nature makes it easy to transport and set up on-site, while its modular design allows for flexibility in creating various wall and column dimensions.

Slabs and Foundations

The formwork is also highly effective in forming concrete slabs and foundations. Its strength ensures that it can withstand the pressure of the concrete, resulting in sturdy, reliable slabs and foundations. Additionally, plastic formwork’s smooth surface ensures an even, high-quality finish on these critical structural components.

Tunnels and Bridges

For larger infrastructure projects, such as tunnels and bridges, plastic formwork provides the durability and flexibility needed to create complex shapes and structures. Its resistance to environmental factors such as moisture and temperature fluctuations makes it a reliable choice for long-term infrastructure projects.

Housing Developments

In housing developments where speed and efficiency are key, plastic formwork helps streamline the construction of concrete walls, floors, and structural components. It allows for quick setup and reuse, ensuring that multiple units can be completed within shorter timeframes without sacrificing quality.

Why Reusable Plastic Formwork is the Future of Construction

The construction industry is rapidly evolving, and innovation is key to staying competitive. Reusable plastic formwork is at the forefront of this change, offering contractors, developers, and builders a solution that meets the growing demands for efficiency, sustainability, and cost savings.

Sustainability is no longer a trend but a necessity, and plastic formwork’s ability to reduce waste and reliance on timber makes it a smart choice for forward-thinking construction companies.

Moreover, efficiency and cost-effectiveness are critical in an industry where delays and budget overruns can make or break a project. By investing in reusable plastic formwork, you can reduce overall project costs, speed up completion times, and deliver high-quality results with less effort.

How to Get Started with Reusable Plastic Formwork

Ready to transform your construction process with reusable plastic formwork? At Measure Manage, we provide high-quality, durable formwork solutions tailored to meet the needs of your project. Whether you’re building residential homes, commercial structures, or large-scale infrastructure, our plastic formwork systems are designed to help you save time, reduce costs, and build more sustainably.

Request a Free Sample or Get in Contact

We’re so confident in the performance of our reusable plastic formwork that we’re offering free samples to help you experience the benefits for yourself.

Want to learn more about how reusable plastic formwork can work for your next project?

Get in touch with us today to speak with one of our experts or to request a free sample and see the difference firsthand.

Transform your construction game and move toward a more efficient, cost-effective, and sustainable future with reusable plastic formwork!